BOSE INTERNSHIP

PRO Continuous Improvement

Mechanical Engineering Intern

Boston, Massachusetts

SKILLS

Lean Manufacturing

Six Sigma

NX 11

Design for Manufacture and Assembly

GD&T

Prototyping

CHALLENGE

Create and develop a tool-free rigging solution for hanging speaker arrays that pass Bose safety standards

OVERVIEW

During my Summer 2019 internship with Bose, I was tasked with creating a tool-free rigging solution that addressed Bose’s issues in the PRO rental market. The current rigging system was structurally sound; however, because speaker riggers prefer the quick pin solution, we needed to change our current rigging setup to include a tool-free rigging setup. We had to achieve this transition without compromising structural integrity or price. Working through a standard design process is difficult enough, but when Contract Manufacturers and Joint Development manufacturers are added in this process, clear communication and precise instructions become increasingly significant. This project taught me how to effectively communicate complex ideas and further developed my understanding of the intricacies of the design process as a mechanical engineer.

MY CONTRIBUTIONS

Concept Generation

I began by exploring using modifications to our current solution versus going with a completely new solution. I created a FRDPARRC table to explore these various solutions. Each unique solution presented me with the potential to maintain strength while increasing usability. The speaker riggers wanted a tool-free device that could replace our current nut and bolt setup. This new device also needed to be attachable to the frame set up in order to be effective in the field.

Decision Matrix

We utilized a decision matrix to decide which product to further pursue. We assumed that all of these potential solutions would pass Bose safety standards which accounts for the lack of safety in the criteria. We decided upon the quick pins because they kept cost low, addressed user needs, and maintained safety.

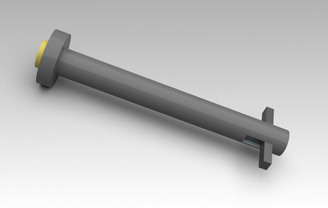

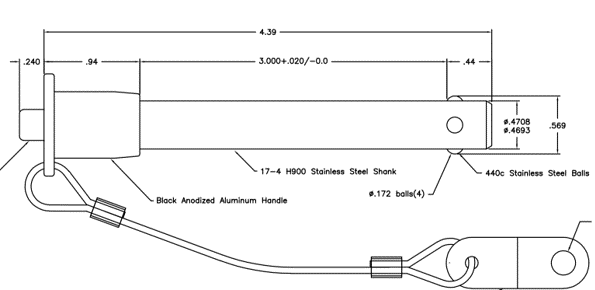

Pin Design & Prototyping

The pin design was done in conjunction with BigSky Manufacturing, one of our contract manufacturers. We needed four ball bearings as a primary constraint on this pin. Normal quick pins only need two ball bearings, but the four-ball ball bearing solution would handle shear forces encountered during the loading process better. We also designed the solution an appropriate length that allowed the ball bearings to hold the multipoint adapter and frame but not protrude too far as to interfere with any other frame components.

Testing

We conducted five tests with the multipoint adapter and two pins. Our tests were loaded on one side as a worst-case loading scenario. These tests provided us with critical information on how our quick pins react under loading scenarios. We discovered that our ball-bearings were not the point of failure as we previously expected; instead, many of the pins failed at the groove of the internal pin where the ball bearings sat. We uncovered vital information that we could use to measure pin performance in loading scenarios.

Final Production

Working to get these pieces into final production presented a few hurdles. We have to maintain cost-effectiveness, quality, and safety. I worked closely with BigSky to design the pins in a manner where we could achieve those three objectives. I switched our metal to a cheaper alternative in the quick pin to maintain our cost-effectiveness without compromising quality and safety. Although taking this design from conception to production was difficult, I learned how to maneuver around the hurdles presented when working with manufacturing teams. The primary hurdle was communicating important technical details to manufacturers through email. I had to explicitly express important specifications for the pin to be effective in the field.

IMPACT & CONCLUSION

Working from conception to production was very fulfilling as an engineering intern. I learned key lessons from this internship that will prepare me for life as a full-time engineer. My biggest takeaway from this project was that creating an effective design is only one step in the process. The communication, execution, and everything else around the project are equally important to the overall success of the product. A poorly managed, executed, or communicated product will prove just as ineffective as a poorly designed product.